Over the past decades, pivot irrigation has become an integral part of modern farming. But what exactly is a pivot irrigation system, which scenarios are best suited, and what are the costs and benefits involved? Here’s a short introduction to Pivot Irrigation.

In a nutshell, pivot irrigation is considered the most efficient method of irrigating large tracts of agricultural land. Since the 1950s, center pivot and lateral move systems have evolved into the go-to choice for ambitious farmers, both in the US and overseas. But let’s start with the basics.

The Structure. A pivot system essentially consists of multiple wheeled towers, which are connected at the top via horizontal pipes (usually made of galvanized steel or aluminum). Water is drawn from a supply point using hydraulic systems or motorized pumps, fed through the pipes and emitted through the sprinklers, which are installed in specific intervals along the pipeline.

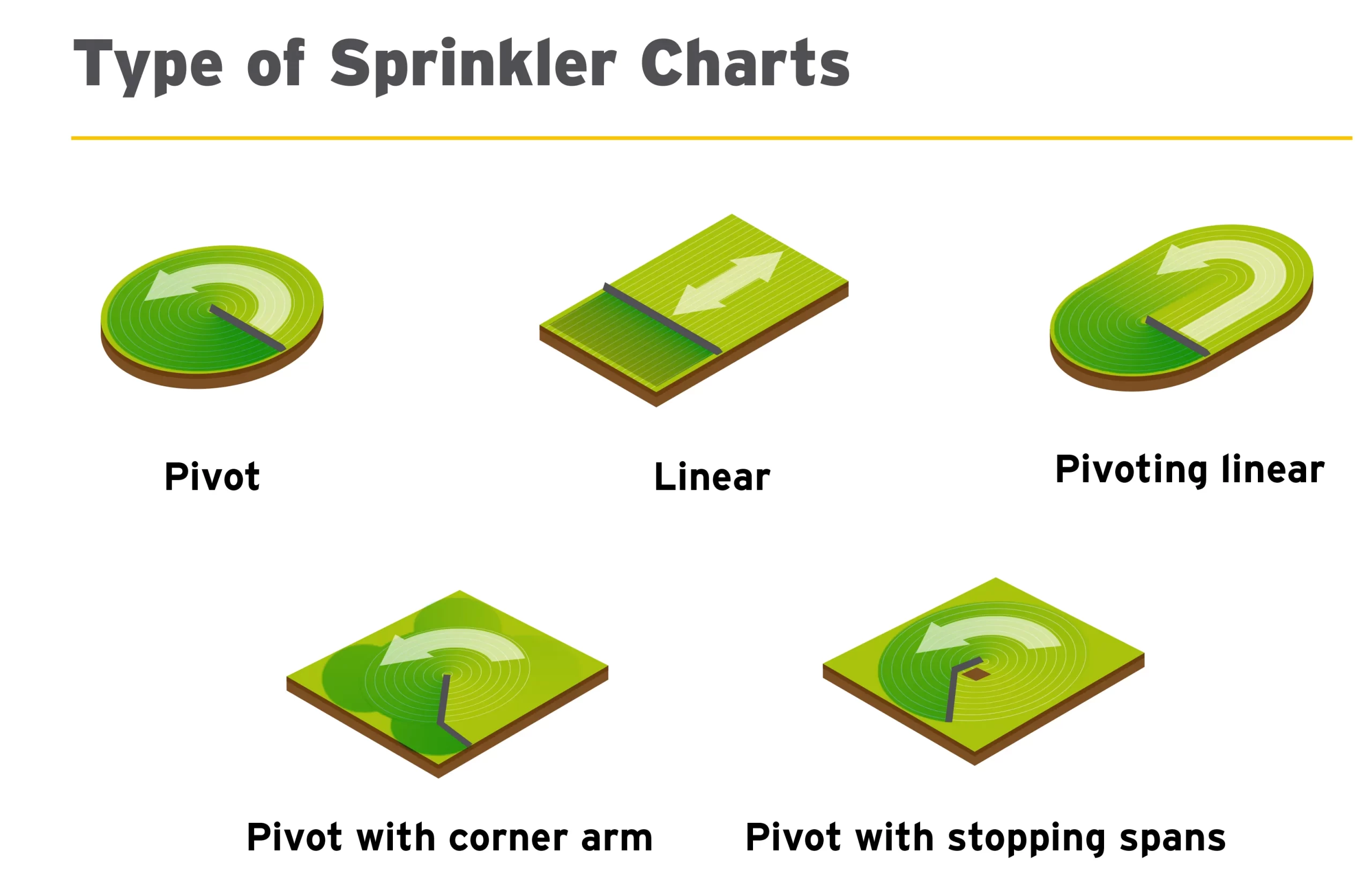

System Types. A fixed center pivot system is attached to a stationary pivot point in the middle of the field; this is where the water enters the pivot pipes, and where the control panel is located. A motor on each wheeled tower enables the structure to move autonomously around the pivot point like the hand of a clock. The result is the circular crop pattern that has become a familiar sight, particularly in rural parts of the US.

Farmers who wish to keep their rectangular field shape (for example, if they have previously used furrow irrigation) might opt for a lateral move system, which works on a similar principle – though its motorized, wheeled towers drive in straight lines, while the water is drawn from a supply ditch that runs parallel to the field. Lateral systems are a popular choice within the cotton industry, and are often found on Australian farms.

A towable center pivot system also produces a circular crop pattern. However, only one end-tower is equipped with wheels, and has to be pulled by a tractor. A towable system can be an economic option for the irrigation of multiple fields, but it entails increased labor and certain restrictions, such as a maximum length for safe maneuvering.

System Sizes. The simplest pivot system available comprises one span with one overhang (80m / 260 ft). The most common length for both lateral and center pivot machines is 400 meters (1/4 mile) – covering around 50 hectares (125 acres) of land. If required, lateral and fixed center pivot systems can reach lengths of around 1000 meters (3280 ft), whereas towable systems should never exceed 500 meters (1640 ft).

The Sprinkler Package. The goal when installing a sprinkler package is to achieve an application uniformity that is as close to 100% as possible, with 90% being considered very high. The exact choice of sprinkler will depend on the crop and soil type, climate, and individual field characteristics. Some of the product traits to consider are the pressure range for which the sprinkler is designed (as this directly translates into energy consumption), its distribution pattern, as well as the nozzle and spray plate design.

To avoid under or overwatering at different sections of the pivot, the correct amount of water must be fed into the sprinkler nozzle at each outlet point. This is achieved by installing a sprinkler system pressure regulator slightly upstream of each sprinkler.

In order to limit wind drift losses and evaporation, sprinkler heads are usually positioned no more than a few feet above the crop – often via ‘drop hoses’ hanging from a U-shaped pipe known as a gooseneck. For tall crops, the sprinklers can optionally be installed on top of the pipe.

Sprinkler Types. The market broadly distinguishes between impact sprinklers and spray heads. Impact sprinklers operate at higher pressures and have a longer throw. They are always mounted on top of the pivot pipeline – often at the end of the center pivot machine (‘end guns’).

Spray heads come in a much wider variety of sub-categories – spanning from simple nozzles and deflector plates, to more complex designs involving rotating, spinning or oscillating plates, with various distribution angles and trajectories. This can make the selection process feel quite daunting. To gain an overview, irrigation dealers, technical sales representatives, as well as the Komet Irrigation Training are excellent ports of call. Learning more about this topic is certainly advisable, as a well-designed sprinkler package – optimized for the soil type, crop and climatic conditions of a given field, and spaced in the right intervals – is a key component of successful pivot irrigation.

Areas of Application. Due to their high adaptability, pivot irrigation systems can be set up in many different terrains – including on undulating ground and (with the proper design) on inclines of up to 30%, though a slope of no more than 15% is recommended. This not only makes pivot irrigation systems suitable for a broad spectrum of geographic regions, but also limits labor-intensive preparations such as leveling fields. In terms of crops, pivot irrigation systems are suitable for virtually all plant varieties – from corn, soybeans and grains to alfalfa, potatoes and vegetables – and can even be adapted to orchards and vines. Pivot irrigation systems are also widely used for fertigation and chemigation.

While pivot irrigation systems are usually associated with large-scale farming, they are also becoming increasingly popular among smallholder collectives. This is partly due to the technological advancements achieved in recent years, which have made pivot systems even more energy-efficient, adaptable, affordable, and easy to use.

Advantages. Pivot irrigation systems are among the most resource-saving methods of agricultural irrigation, with up to 98% water use efficiency compared to low-tech methods such as flood irrigation. State-of-the-art sprinklers tend to be designed for low-pressure operation (a prime example being the high-performance center pivot sprinkler KPT with a minimum operating pressure of 6 psi), resulting in significantly lower energy costs. Once set up, center pivot and lateral move systems operate autonomously, requiring very little labor aside from some routine annual maintenance. In addition, being able to fine-tune factors such as droplet size, emission angles and application rates allows for a better absorption of the water into the soil – whereas with less sophisticated methods, up to 50% of the applied water can be lost through runoff; at the same time, increasingly advanced pivot software enables growers to precisely monitor parameters such as operational performance and energy use , and make the necessary adjustments for optimal results.

A Brief History. In 1948, an ingenious Nebraskan farmer named Frank Zybach built his first prototype for an invention that would change the world of agriculture: in 1952, his “Self Propelled Sprinkling Irrigation Apparatus” was officially patented. Zybach initially tried to sell the system in his local area, but the “new-fangled contraption” was met with more skepticism than success. Things started to look up when he licensed his design to a small manufacturing company, located on a farm outside of Valley, Nebraska. Before too long, the company was producing 50 units of his “apparatus” every year – and other US manufacturers soon followed suit.

All the way across the Atlantic Ocean, another pioneering spirit recognized the potential of mechanized irrigation: a young entrepreneur named Roland Drechsel – whose three sons are now at the helm of Komet Irrigation. In the early 1950s, Drechsel spearheaded the European market with his novel production site for mechanized impact sprinkler irrigation. And the rest, as they say, is history.

Investment. The initial outlay of around 100,000 USD (based on a standard American-style system with a coverage of around 120 acres, and including a 5,000 to 10,000 USD sprinkler package) is, of course, a point of consideration for anyone looking to convert to center pivot irrigation. However, in view of today’s changing weather patterns, water scarcity, and soaring energy and labor costs, it is a one-off investment that is sure to yield long-term profitability. A cost-per-use calculation can also help put things in perspective, given that center pivot systems have an average lifespan of around twenty to twenty-five years.

The Future of the Irrigation Market. Canada and the US currently account for around 50% of the global center pivot market, with the other 50% attributed to the rest of the world combined. However, this is slowly shifting. Other countries are rapidly adopting this highly effective method of agricultural irrigation – while North America (where center pivots have been utilized since the early 1950s) is a mature market with less room for further growth. In fact, center pivots are the primary method of irrigation across the American Great Plains. In 2011, there were an estimated 55,000 center pivots in Nebraska alone – a number that is sure to be even higher today. Brazil, on the other hand – whose agricultural sector has long been a primary cornerstone of its economy – is now tipped to be the next major territory for mechanized irrigation.