Our in-house experts take a look at center pivot and linear irrigation systems, their basic operating principles, and the latest labor-saving technology.

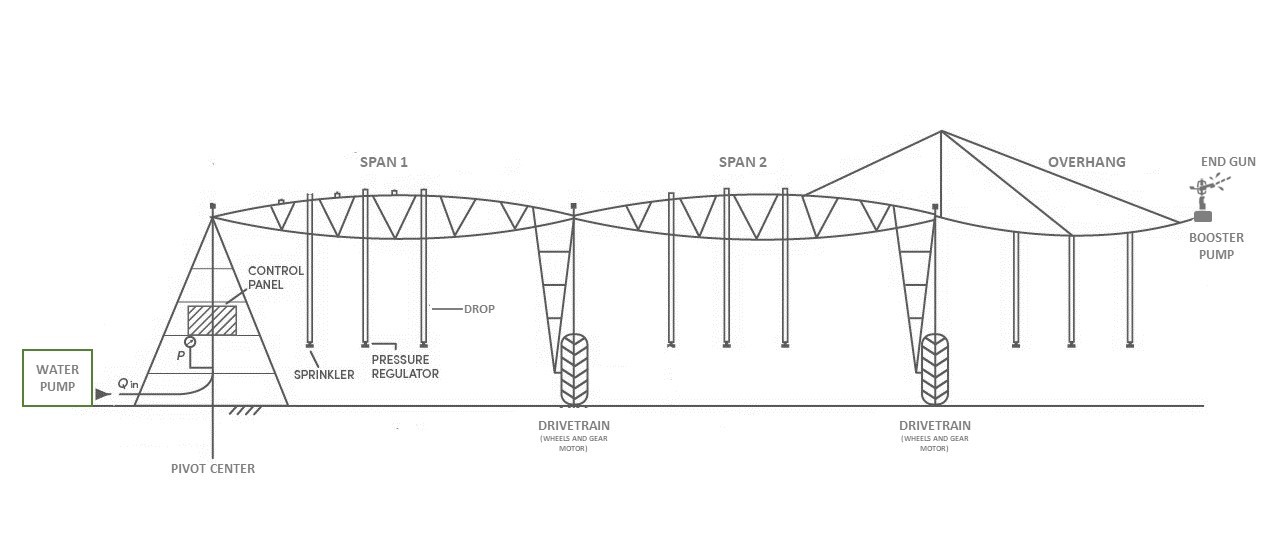

Operating principles. Center pivot irrigation is essentially the distribution of water through an elevated pipeline that rotates around a central point (pivot center). The water is pumped to the pivot center from a source (such as a ground water aquifer, a manmade surface water storage, or a natural river, pond or lake), fed into the pivot, and applied to the soil by sprinkler devices that are mounted along the length of the pipeline.

In some cases, an additional high-volume sprinkler (end gun) is mounted on the end of the center pivot system, in order to water areas of the field that the main pipeline cannot reach. This enables growers to utilize every inch of fertile soil, seeing as most fields are square or rectangular, whereas the center pivot irrigates the ground in a circle. The speed at which the pivot machine is moving determines the amount of water applied to the soil and crop.

Components of a center pivot system:

• Pump at the water source

• Pipeline from the pump to the pivot center (known as the mainline)

• Control panel

• Pivot center

• Span pipe

• Towers

• Drivetrain (wheels and gear motors)

• End boom

• Sprinkler mounting devices (drop tubes, or pipe nipples)

• Pressure regulators

• Sprinklers

• End gun and booster pump

Range of lengths. Within North America, center pivot systems with a length of around 1300 feet (396 meters) are considered standard. Depending on the field requirements and available water supply, center pivot systems can range from a single span plus overhang (260 feet / 80 meters) to 2800 feet (855 meters) or more.

Circular vs. linear. Since its invention in the late 1940s, pivot irrigation has undergone significant developments – including numerous adaptations to the system itself. For example, farmers now have a choice between center pivot and lateral (linear) move systems.

With a center pivot system, the pipe structure moves around a central ‘pivot point’ like the hand of a clock – resulting in a circular crop pattern. A lateral move system, by contrast, uses a mobile ‘pivot cart’ to travel in a straight line.

Linear irrigation systems provide full coverage of a square or rectangular shaped field. But they not only have a higher purchase price, but are also more complicated to run and manage, and pose more limits in terms of installation compared to their center-pivot counterparts.

Linear irrigation systems provide full coverage of a square or rectangular shaped field. But they not only have a higher purchase price, but are also more complicated to run and manage, and pose more limits in terms of installation compared to their center-pivot counterparts.

For the best of both worlds, many farmers choose to install a corner arm at the end of their center pivot machine. This is essentially an additional span that swings out to water the corners of a square or rectangular field, in order to irrigate those sections that would otherwise be lost due to the circular path of the center pivot.

Dual purpose. In addition to ensuring reliable crop irrigation, pivot systems can also be used to apply chemicals and fertilizers through the system’s existing sprinklers. Nutritious compounds and agro-chemicals (such as fungicides etc.) can be distributed in a highly efficient manner. This reduces pollution and waste, and saves growers from having to purchase additional equipment – creating both an economic and ecological advantage.

Work smarter, not harder. The number of people working in agriculture is rapidly declining, leaving modern farmers to take on more and more tasks themselves. This is one of many reasons why growers are turning to pivot systems as a highly automated and labor-saving form of crop irrigation, which is further aided by increasingly sophisticated technology.

GPS, for example, enables the remote guidance of corner arms and linear machines, as well as the exact positioning of the irrigation system for Variable Rate Irrigation (VRI). Telemetry even goes a step further, by allowing farmers to start, stop and monitor the system via a smartphone or computer – including key parameters such as soil moisture (for irrigation scheduling), tank or pond levels (to prevent overflows or disrupted schedules due to shortages), weather conditions (including wind speed, barometric pressure and solar radiation), and much more.

To delve deeper into the topic of pivot irrigation, see our introduction to pivot irrigation, the Komet Academy, as well as the Komet blog and our social media posts!