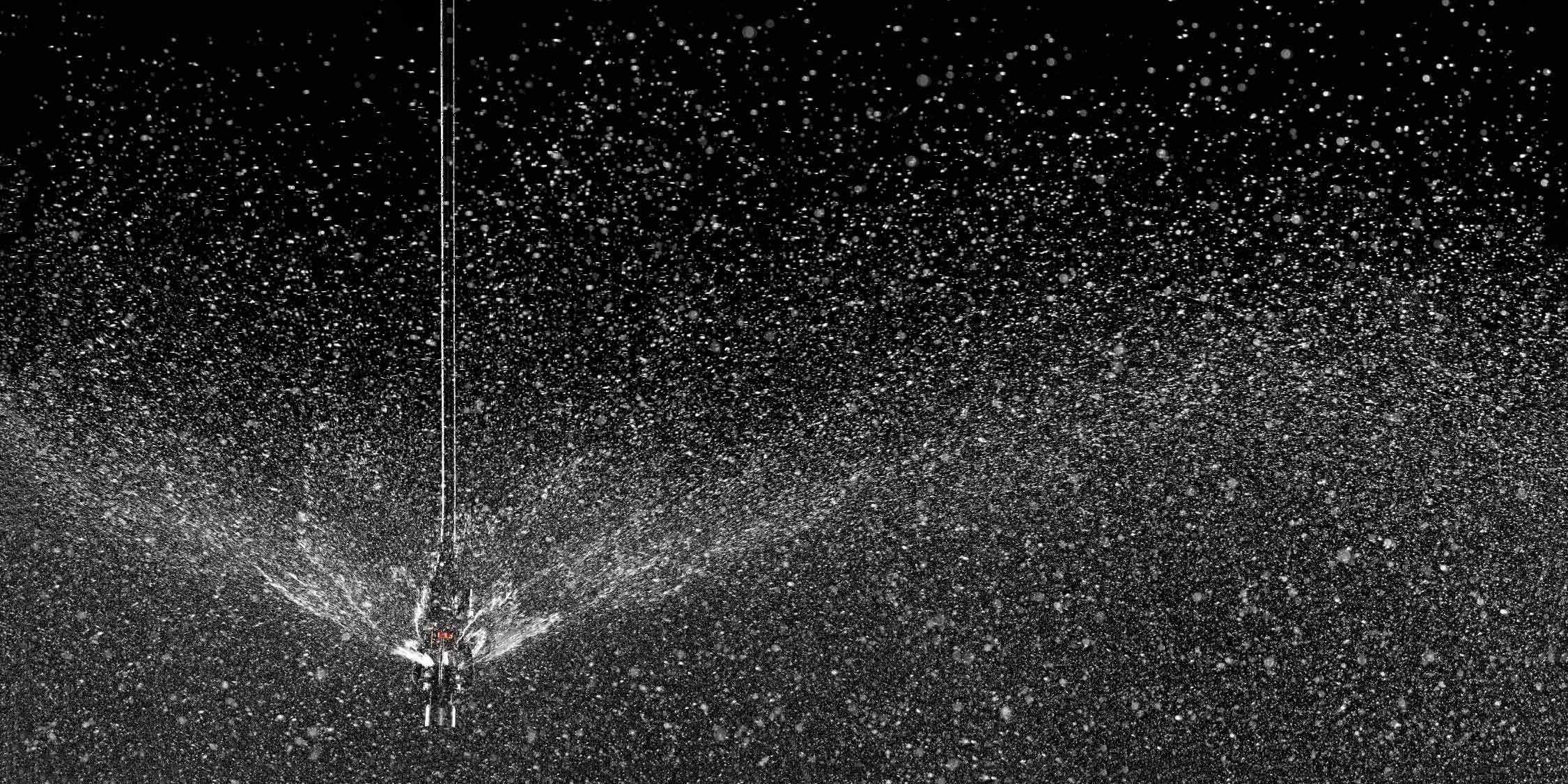

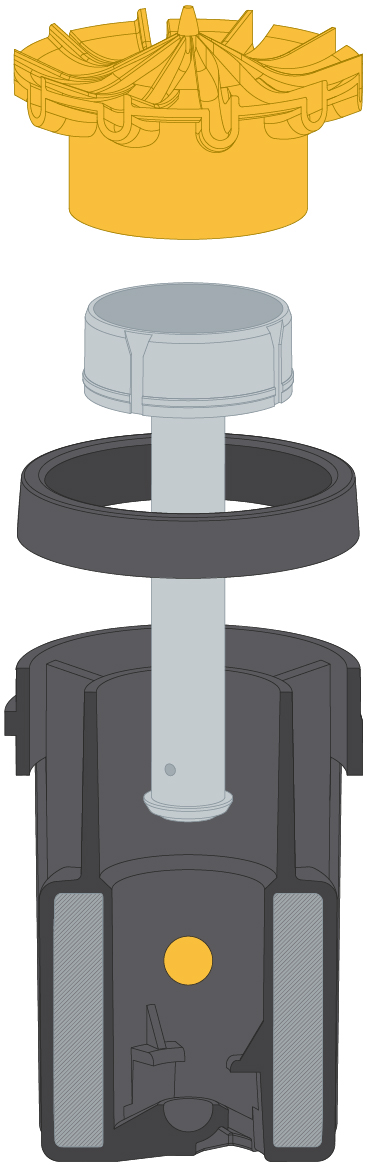

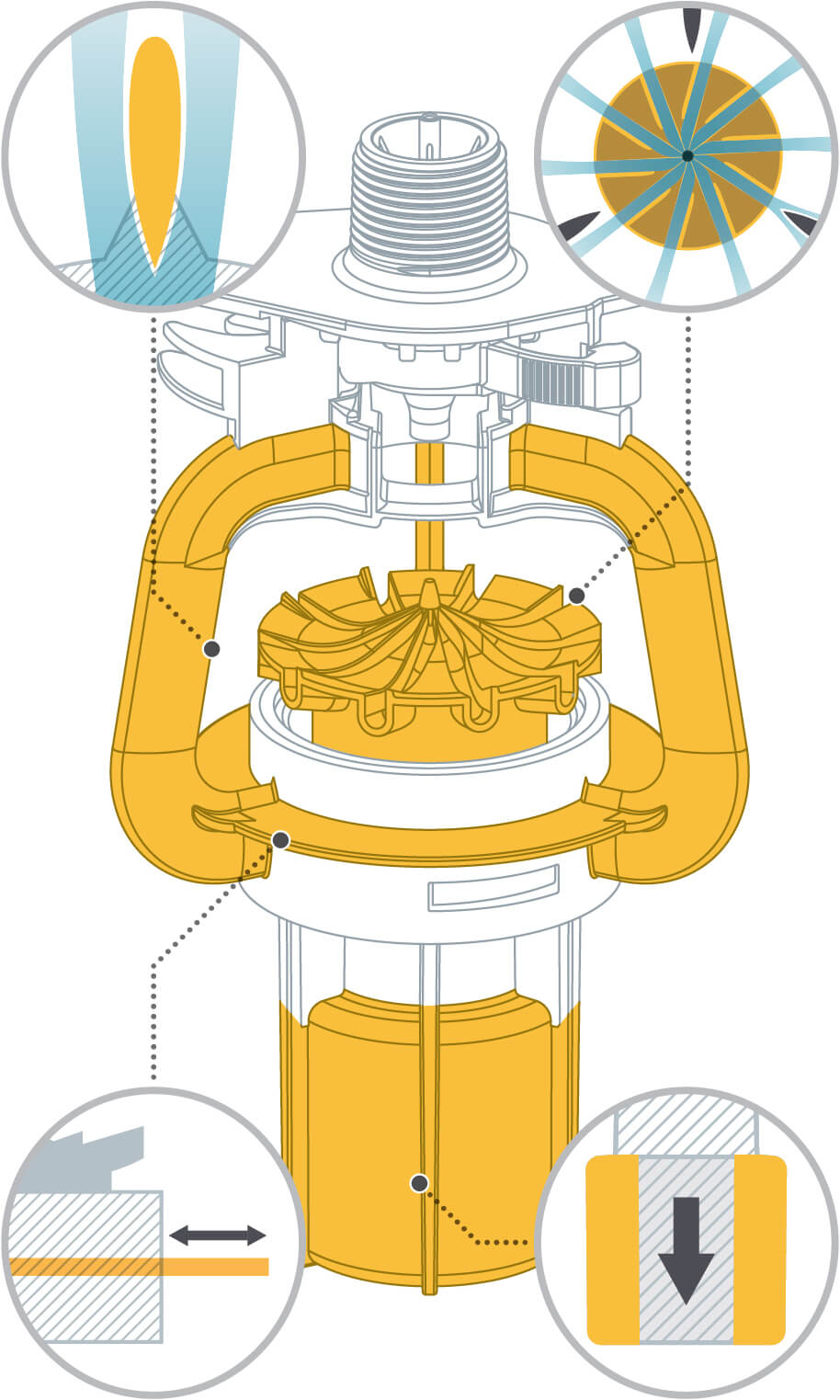

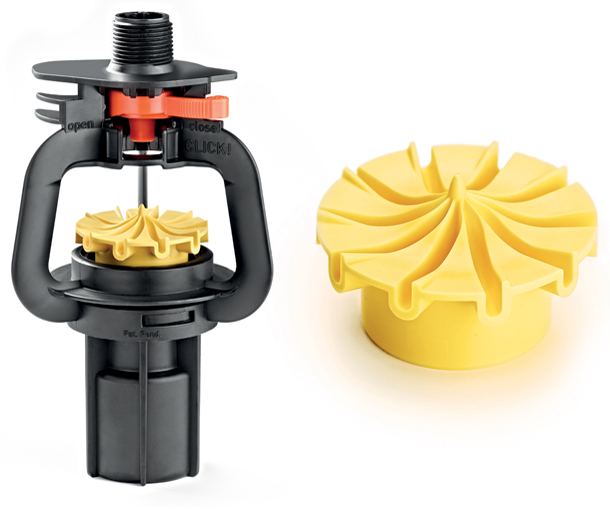

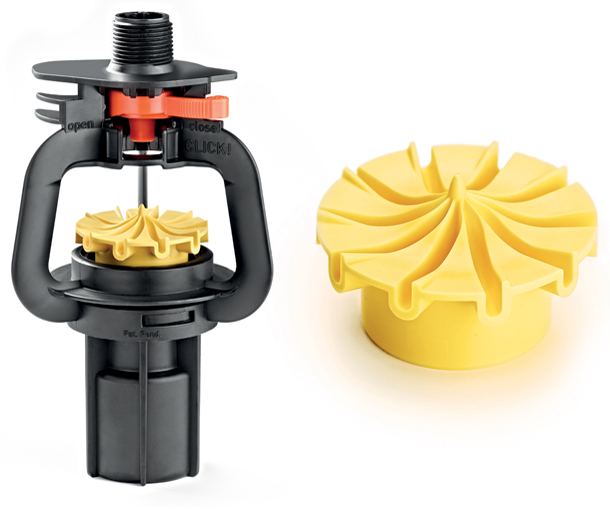

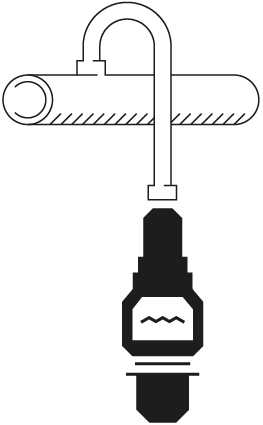

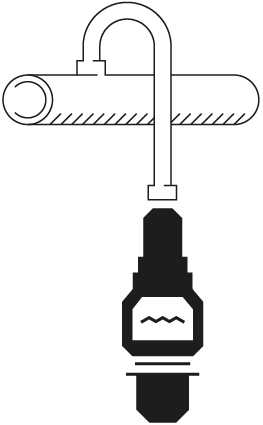

Komet’s 3-D Motion System gives the best possible result of uniform water distribution within the whole distribution pattern. The capability of superior water distribution is derived from a combination of components working together, among them, the very responsive 3-D bearing built into the Komet Precision Twister (KPT) sprinkler. This bearing allows the movement of the deflector around the central axis of the sprinkler as well as the deflector’s own axis. As the water flows through the sprinkler in its central axis, the deflector oscillates around this central axis, diverting precise amounts of water radially into the air for effective droplet dispersion starting at very low pressures.

Pivot

Sprinkler

Products

Advantages

Uniform Water Distribution

Efficient irrigation is one of the most important factors in crop production...

Read more

Consistency of Droplet Size

For the best irrigation performance two factors are crucial, reducing the kinetic...

Read more

Energy Efficiency

Pressure is a major factor in determining the operating cost of an irrigation...

Read more

Reliability

Intensive farming practices require that every irrigation system operates reliably...

Read more

Adaptability

It is fundamental that a pivot sprinkler adapts to different application conditions...

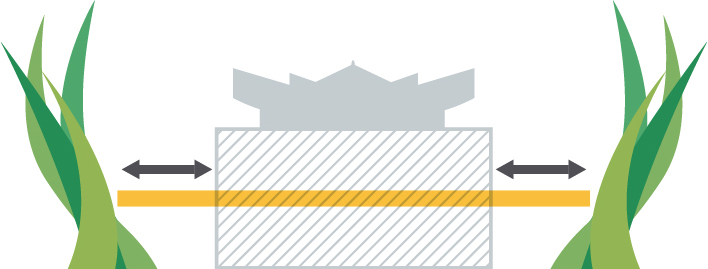

Read moreEfficient irrigation is one of the most important factors in crop production. A uniform water application within the wetted pattern, combined with proper overlap of the individual sprinkler patterns, distributes the water evenly across the crop area – thus giving the water the best opportunity to infiltrate into the root zone. In addition, a uniform water distribution over the entire wetted diameter of the sprinkler keeps the instantaneous application rate low, which reduces the chance of ponding and runoff.

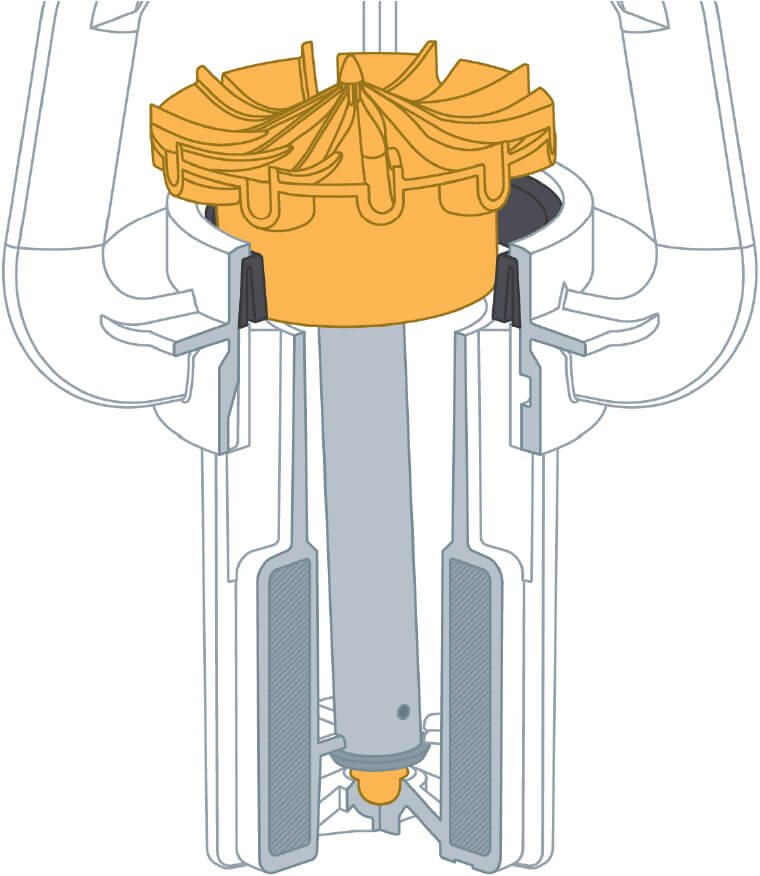

Komet 3D Motion System

-

The deflector rotates around the central sprinkler axis as well as its own inclined axis.

Large Wetted Diameter

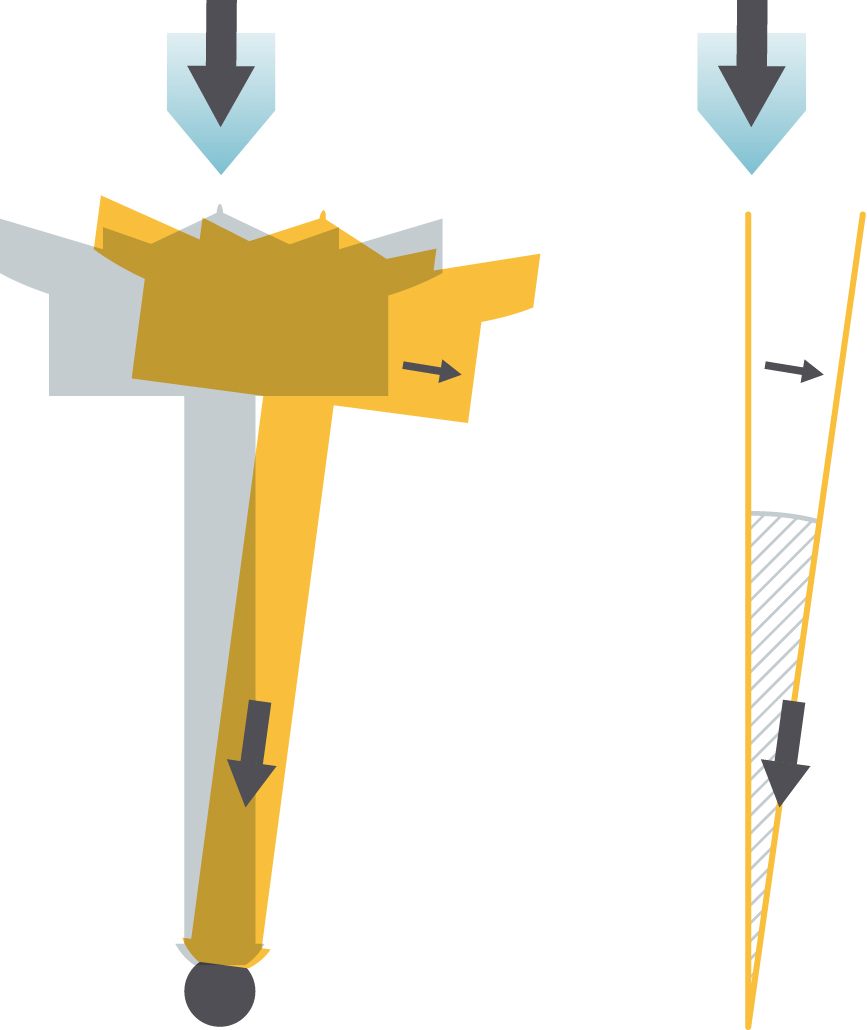

Because of the 3-D motion of the deflector, the water is radially diverted into a sequence of effective, precise amounts of water. This gives the Komet Precision Twister (KPT) its impressive throw, while maintaining consistent distribution uniformity throughout its range of operation.

Reduced Dripping

The specially designed body legs of the Komet Precision Twister (KPT) provide minimal interference for the water streams as they exit the deflector grooves. This combined with the odd number of body legs and the even number of deflector grooves, a configuration unique to the industry, reduces dripping to a minimum.

-

The even number of streams and odd number of specially designed body legs means that only one stream hits a body leg at any given time.

Komet Universal Pivot Sprinkler

The superior operation of the Komet Precision Twister (KPT) sprinkler also at low pressures and flow rates, and its consistent distribution pattern from the pivot point to the end, allows the use of one sprinkler throughout the entire irrigation system. The sprinkler distributes the water effectively in a pressure range from 6 to 20 psi and a nozzle range from 10/128” up to 52/128”. This feature is unique to the industry making it unnecessary to use different sprinkler types on the same system. Different sprinklers along one system deliver different water distribution profiles contributing to an overall inferior system performance.

Komet Precision Twister (KPT)

Standard trajectory angle

#30 nozzle size

10 psi pressure

10 ft spacing

For the best irrigation performance two factors are crucial, reducing the kinetic energy of the water impact onto the soil and controlling wind drift. Delivering a consistent droplet size greatly reduces the loss from wind drift of the fine droplets/mist. In addition, a controlled consistent droplet size and uniform distribution of the droplets within the sprinkler pattern reduces the impact force typical of larger droplets on the soil. These kinds of droplets can cause soil sealing which in turn reduce the soil’s water intake rate, increasing the possibility of runoff and thus keeping the water from reaching the target root zone.

Typical droplet distribution of competitive devices

Droplets too large

Droplets too fine

Komet Precision Twister (KPT) - Droplet distribution

Optimized droplet size consistency over whole wetted diameter

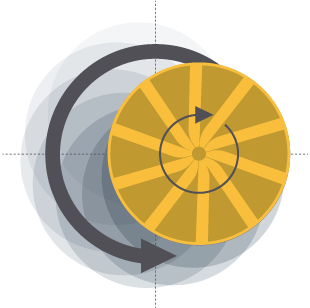

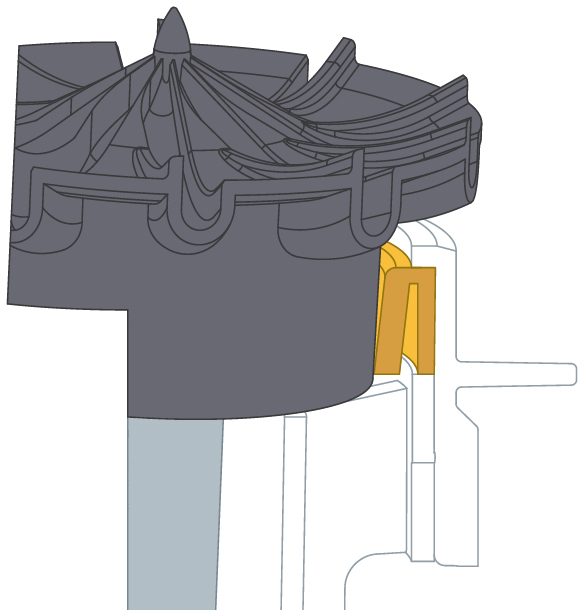

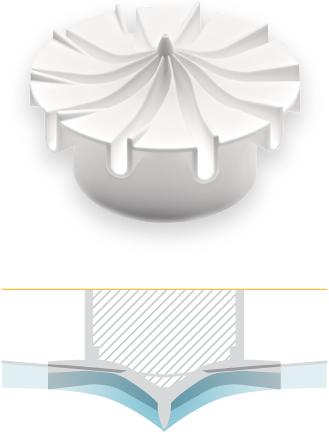

Komet Automatic Motion Control

-

In addition to the 3-dimensional rotation around the central sprinkler axis, an elastic ring with a flexible inner wall controls the motion of the deflector around its own axis. This feature greatly supports the uniform water distribution of the Komet Precision Twister (KPT) throughout the entire range of pressure and flow conditions.

-

In low flow conditions, friction is kept to a minimum for best performance with small nozzles.

-

With increasing flows, the outer ring gradually adapts itself to the deflector for constant performance throughout the whole nozzle range.

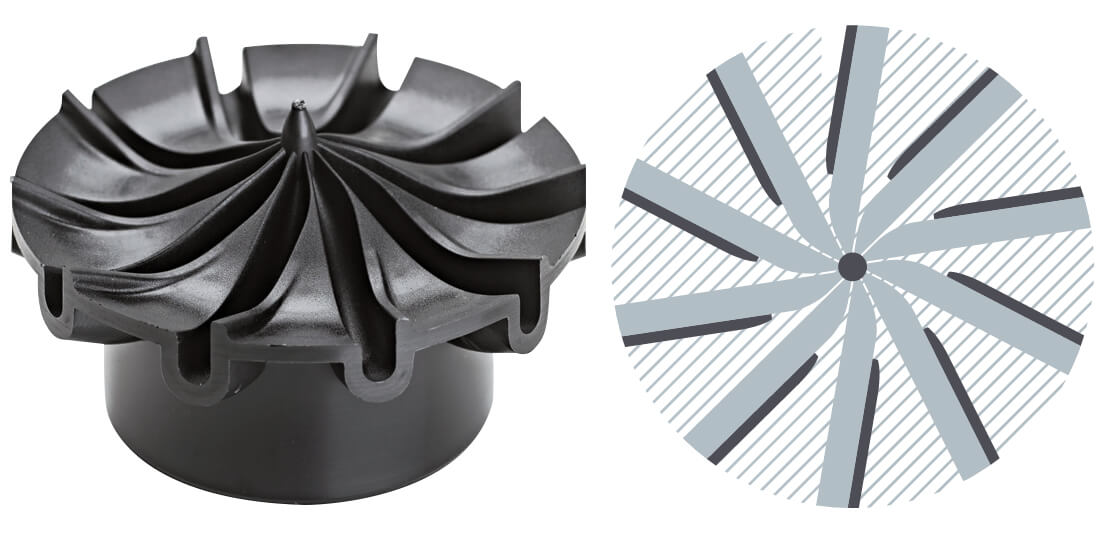

Komet - Deflector

and Groove Configuration

-

Optimized flow of water through the groove from entrance to exit.

Intensive research and testing made it possible to achieve a droplet distribution pattern that is unique in the industry.

The special groove configuration and surface design of the deflector makes sure the water is channeled and properly broken up upon exiting the grooves, dispersing into consistent water droplets over the sprinkler’s entire wetted area throughout its range of operation. The Komet Precision Twister (KPT) groove design has been highly engineered to reduce very fine droplets and misting to a minimum in order to maximize the overall system performance.

Komet Precision Twister (KPT)

Standard trajectory angle

#30 nozzle size

10 psi pressure

10 ft spacing

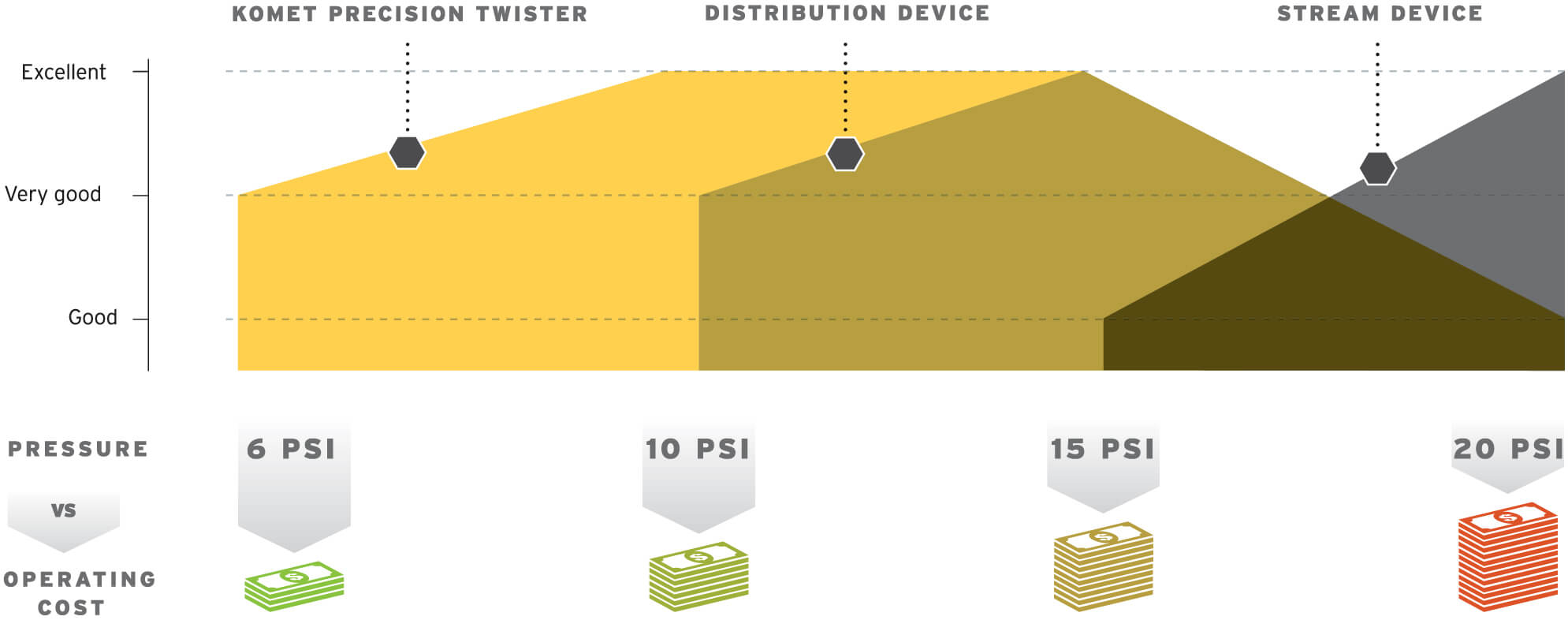

Pressure is a major factor in determining the operating cost of an irrigation system. The higher the pressure required to operate it, the higher the operating cost will be. Finding a method to limit the operating pressure requirement without sacrificing the quality of the water distribution uniformity is ideal. Upgrading the efficiency of the irrigation system can help to increase yields while reducing the operating costs.

Komet - Operating Pressure

In today’s farming world, the input costs, such as energy, are closely considered. The design of the innovative Komet Precision Twister (KPT) focuses on efficiency in operation. This precision device has excellent performance at 10 psi and 15 psi and very good performance at 6 psi. Its operating range is the most extended in the industry in this class of device.

-

Optimal operating pressure for most common devices

-

Sprinkler Device Efficiencies

Komet Elements with Low Inertia

Komet has designed a sprinkler that can effectively help reduce energy inputs by allowing the irrigation system to operate at lower pressure while maintaining excellent water distribution uniformity. The Komet 3-dimensional motion system reacts very responsively to minimal pressure and flow levels making the Komet Precision Twister (KPT) sprinkler work more efficiently at lower pressures than other sprinklers. There is no need for additional starting devices built into the sprinkler and therefore no risk of wear of such critical parts that could cause start-up failures.

Komet Precision Twister (KPT)

Standard trajectory angle

#30 nozzle size

Below 6 psi pressure

Intensive farming practices require that every irrigation system operates reliably in order to maximize crop potential. Timing of water application is critical to the potential yield of the crop, especially during dry conditions. Therefore it is essential for growers to use only highly reliable products.

Komet - Designed for Reliable Operation

-

The down force of the water stream is concentrated onto the 3-D bearing situated along the central axis of the sprinkler. The force diagram shows the minimal force put on the elastic ring.

We believe that reliability needs to be strongly considered in the early stages of product design. The Komet 3-D motion system concentrates the water force onto the patented 3-D bearing situated along the central axis of the sprinkler, thus putting very little stress on the sprinkler assembly. For applications where in-canopy operation is required, a crop guard is built into the main body of the Komet Precision Twister (KPT) sprinkler. The crop guard prevents the deflector from stalling, adding reliability to the sprinkler.

-

A crop guard keeps the deflector rotating also in tall crops.

Komet - Smooth Operation for more Reliability

The unique configuration of the odd number of the body legs in conjunction with the even number of deflector grooves further contribute to the very smooth operation of the Komet Precision Twister (KPT). The strategic positioning of the integrated weight allows it to keep vibration levels to the lowest in this class of device and helps to keep the sprinkler steady in windy conditions. All of the above factors contribute to the outstanding reliability of the Komet Precision Twister (KPT).

Komet - Quality and Materials

The precision manufacturing of every component includes strict quality controls during every manufacturing step and the utmost care in selecting the appropriate materials. The use of shock proof and UV resistant technical polymers, special fiber reinforced and high technology parts are key elements in making the Komet Precision Twister (KPT) a sprinkler of outstanding quality and reliability for most climatic and water conditions.

Komet - Field-Proven Technology

Because reliability is so important to us, we have tested the Komet Precision Twister (KPT) sprinklers over many irrigation seasons. Test sites included a variety of terrains, soils, water conditions, crop types and climatic conditions.

-

Only one stream at a time interferes with the body legs for a smooth operation.

The shape of the body legs contributes to a smooth flow of the water around them.

It is fundamental that a pivot sprinkler adapts to different application conditions while maintaining excellent performance. The sprinkler must be able to cope with a wide range of environmental factors such as soil type, terrain, atmospheric conditions, water quality as well as different crops. For optimal irrigation the grower must have the ability to adapt to its prevailing factors

Komet - Trajectory Angles

Working closely with growers allowed us to identify and develop four different deflectors to maximize the irrigation efficiency for different application requirements.

For use on drops: Standard angle suitable for most applications, low angle for applications in windy conditions or where higher ground clearance is required without water interfering with the pivot structure and ultra-low angle for extreme conditions such as high winds, high heat and/or low flow and where it is most important to get the water to the soil.

For use on top of pipe: Low profile trajectory suitable for all applications when sprinkler installation on top of pipe is required.

-

Standard Trajectory Angle

For use on drops

-

Low Trajectory Angle

For use on drops

-

Ultra-Low Trajectory Angle

For use on drops

-

Low Profile Trajectory

For use on top of pipe

-

Part Circle Sprinkler

For use on rigid drops

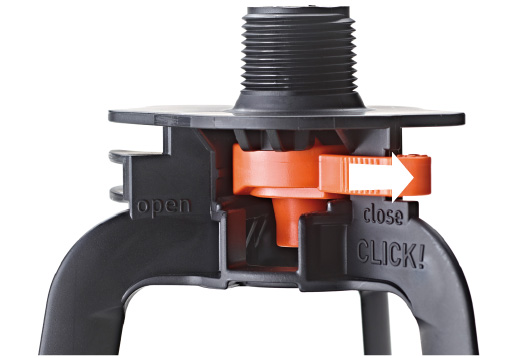

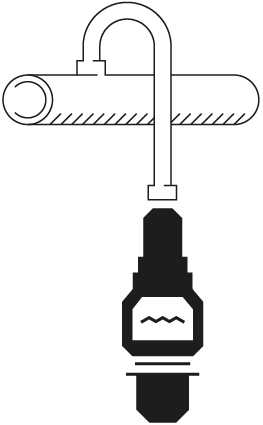

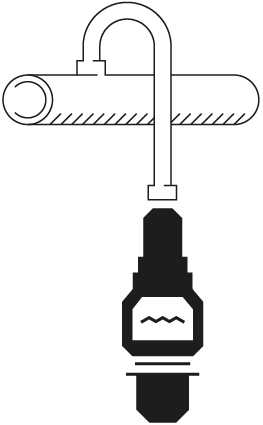

Komet Rapid Fit Nozzle System

The Komet Rapid Fit Nozzle System allows for a fast and easy installation of the nozzle into the sprinkler. There is no need to remove the sprinkler from the drop assembly should the nozzle be plugged or in case it needs to be changed for different flow requirements. The nozzle can be removed for cleaning or replacing while the sprinkler is operating.

-

1. Insert

-

2. Rotate to install

-

3. Click to secure

Komet integrated additional nozzle carrier

The Komet Precision Twister (KPT) comes with a second nozzle carrier integrated into the sprinkler body. It is very useful should the irrigation require different flow rates during the irrigation season.

Komet Truss Rod Clip

Lowering the application rate, can be a decisive advantage in irrigation. A suitable olution is to increase the wetted area by using drops over the truss rod, fi xed with the Komet Truss Rod Clip. The design of the Komet Truss Rod Clip allows for an easy fi xation on the truss rod while maintaining the natural shape of the hose. To facilitate selection, 4 models with two size combinations each are available, covering all common rod sizes.

Komet Precision Twister (KPT)

#30 nozzle size

10 psi pressure

10 ft spacing

Standard trajectory angle

Komet Precision Twister (KPT)

#30 nozzle size

10 psi pressure

10 ft spacing

Low trajectory angle

Komet Precision Twister (KPT)

#30 nozzle size

10 psi pressure

10 ft spacing

Ultra-low trajectory angle

Komet Precision Twister (KPT) PC-180°

product!

- Nozzle Range

- 39 nozzles

2.8 – 10.3 mm

14 – 52 1/128″

- Flow range

- 196.3 – 4175.5 l/hr

0.86 – 18.38 gpm

- Throw range

- 3.2 – 8.5 m

10.4 – 27.8 ft

at 1.8 m (6 ft)

ground clearance

Download

Catalogue

Komet Pivot Sprinkler

Technical information

Operating Instructions

KPT PC-180°

Operating Instructions

Rapid Fit Nozzle

Operating Instructions

Rapid Fit Nozzle Tool

Komet

Precision Twister

(KPT)

- Nozzle Range

- 43 nozzles

2.0 – 10.3 mm

10 – 52 1/128″

- Flow range

- 100.7 – 4844.4 l/hr

0.44 – 21.33 gpm

- Throw range

- 9.0 – 16.8 m

30.0 – 55.0 ft

at 1.8 m (6 ft)

ground clearance

Download

Catalogue

Komet Pivot Sprinkler

Technical information

Operating Instructions KPT

Operating Instructions

Rapid Fit Nozzle

Operating Instructions

Rapid Fit Nozzle Tool

Available models

Komet Precision Twister (KPT)

Standard Angle

For use on drops

Flex hose drop

Poly pipe drop

Description of allowed drop types

- Flex hose drop

- Semi-rigid poly drop: drop must have a min. of one steel adapter which must be installed on the gooseneck side. Poly pipe must be low-medium density

- Not for use on rigid PVC or steel drops

- Other installation options will void the warranty

Komet Precision Twister (KPT)

Low Angle

For use on drops

Flex hose drop

Poly pipe drop

Description of allowed drop types

- Flex hose drop

- Semi-rigid poly drop: drop must have a min. of one steel adapter which must be installed on the gooseneck side. Poly pipe must be low-medium density

- Not for use on rigid PVC or steel drops

- Other installation options will void the warranty

Komet Precision Twister (KPT)

Ultra-Low Angle

For use on drops

Flex hose drop

Poly pipe drop

Description of allowed drop types

- Flex hose drop

- Semi-rigid poly drop: drop must have a min. of one steel adapter which must be installed on the gooseneck side. Poly pipe must be low-medium density

- Not for use on rigid PVC or steel drops

- Other installation options will void the warranty

Komet

Precision Twister

(KPT) Peak

- Nozzle Range

- 43 nozzles

2.0 – 10.3 mm

10 – 52 1/128″

- Flow range

- 100.7 – 4844.4 l/hr

0.44 – 21.33 gpm

- Throw range

- 12.0 – 19.2 m

39 – 63 ft

at 4 m (13 ft)

ground clearance

Download

Catalogue

Komet Pivot Sprinkler

Technical information

Operating Instructions KPT-Peak

Operating Instructions KPT Link

Operating Instructions

Rapid Fit Nozzle

Operating Instructions

Rapid Fit Nozzle Tool

Available models

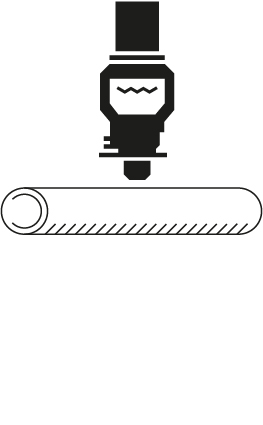

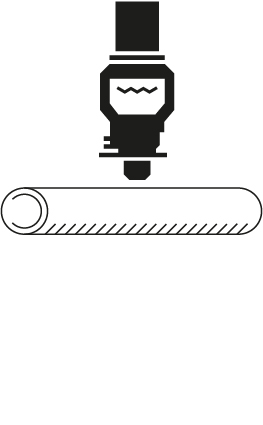

Komet Precision Twister (KPT) Peak

Low Profile Trajectory

For use on top of pipe

Komet KPT-Link connector

Allowed type of installation

- For use on top of pipe only

- Install the Komet KPT-Link connector between the regulator and the Komet Precision Twister (KPT-Peak)

- The non use of the Komet KPT-Link connector will void the warranty

- Use a steel nipple at the outlet

- Other installation options will void the warranty

Komet

Precision Twister

(KPT) PC-180°

Part Circle

- Nozzle Range

- 39 nozzles

2.8 – 10.3 mm

14 – 52 1/128″

- Flow range

- 196.3 – 4175.5 l/hr

0.86 – 18.38 gpm

- Throw range

- 3.7 – 9.4 m

12.2 – 30.7 ft

at 1.8 m (6 ft)

ground clearance

Download

Catalogue

Komet Pivot Sprinkler

Technical information

Operating Instructions

KPT PC-180°

Operating Instructions

Rapid Fit Nozzle

Operating Instructions

Rapid Fit Nozzle Tool

Available models

Komet Precision Twister (KPT) PC - 180°

Part Circle

For use on drops

Rigid drop

Description of allowed drop types

- Galvanized steel drop

- Other installation options will void the warranty

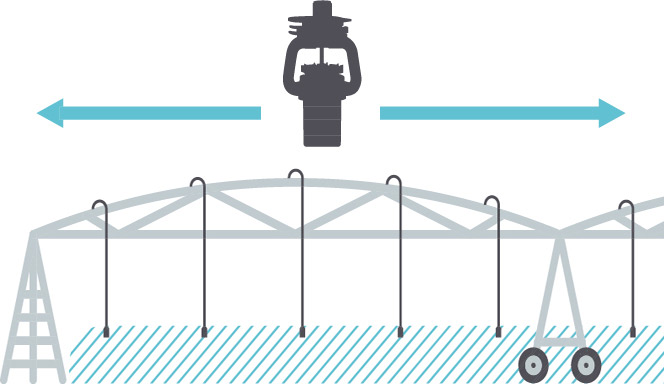

Center Pivot Sprinkler Irrigation: Benefits & Considerations

For most landowners, a center pivot irrigation system is one of the most important investments they will ever make. Despite the initial outlay, the cost-benefit ratio is extremely favorable in the long term, particularly in areas where natural precipitation can be irregular or scarce.

As vital as the mechanized system itself is choosing the right center pivot sprinklers. To achieve optimal results (in other words: a high yield of healthy crops, good soil integrity, and an efficient performance of the center pivot irrigation system both in terms of water and energy usage), the center pivot sprinkler package should be designed with several factors in mind.

For example, different crops require different application rates for their development and growth. This should always be reflected in the type of sprinkler heads installed. Also, in order to achieve an uninterrupted, evenly wetted area, the right number of center pivot sprinklers must be positioned along the pipeline with the correct spacing, as this ensures maximum water application uniformity.

Growers should also be aware of the depth, consistency and texture of the soil, as this determines how fast the water emitted by the center pivot sprinklers is absorbed by the soil. This is known as the infiltration rate, and is usually expressed in inches per hour. The infiltration rate primarily depends on the percentage of sand, silt and clay in the soil. Sandy soils, for example, have a high infiltration rate, as the water moves more quickly through its larger pores. Heavier, clay-rich soils, on the other hand, generally have a lower infiltration rate, as they have small pores and very little structure or aggregation. As a result, clay-heavy soils are especially prone to surface sealing and compaction, and therefore require a lower application rate.

While the application rate is something that can be adjusted, it is worth bearing in mind that every center pivot sprinkler model is manufactured and designed to operate within a specific flow range. Deviating from this stipulated range might interfere with the sprinkler head’s intended distribution pattern (resulting in uneven watering of the crop) and can also lead to premature equipment wear.

As a rule, the application rate of the center pivot sprinkler must always match the infiltration rate of the soil. If they are out of sync, this can result in runoff (especially if the terrain is sloping), as well as under or over-watering of certain parts of the field.

Which brings us to the size of the droplets emitted by the center pivot sprinkler – a crucial factor in maintaining both soil integrity and crop health. Larger droplets generate a high kinetic energy; this can not only damage seedlings and more sensitive crops, but might also disrupt the texture of the soil, causing surface sealing and compaction. This, in turn, prevents the water from reaching the roots where it is needed. Droplets that are too small, on the other hand, are much more prone to misting and evaporation. Ideally, therefore, a center pivot sprinkler should emit droplets that are large enough to withstand wind drift, misting and evaporation, but small enough to avoid surface sealing, compaction and erosion on tighter soils.

Komet Sprinkler Heads for Center Pivot Irrigation Systems

Komet’s sprinkler heads are sophisticated, highly engineered distribution devices that are specifically designed to strike this balance. With the Komet Precision Twister (KPT), for example, the company has used its in-depth research into an optimized droplet size to produce a center pivot sprinkler that can be installed along the entire irrigation system, and is suitable for crop types across the board. The KPT is intended for installation on flex-hose, combi drops (semi-rigid poly and hose) and semi-rigid poly drops, and meets all of the requirements that were identified in Komet’s studies on high-efficiency irrigation – including the ability to operate at low pressures.

A genuine all-rounder, the Komet Precision Twister (KPT) is also available as a top-of-pipe variant – aptly named the Komet Precision Twister (KPT) Peak. With its consistent distribution pattern and excellent wind-drift resistance, the KPT Peak can be installed above the plant canopy to effectively irrigate tall-growing field and tree crops.

The third variant in Komet’s KPT center pivot sprinkler range is the Komet Precision Twister (KPT) PC-180 part circle sprinkler – a game-changer in the field of 180-degree irrigation. A part circle sprinkler is a sprinkler that sprays water in a 180° (half circle) pattern. Part circle sprinklers are typically installed around the tower of a center pivot irrigation system. Their purpose is to irrigate crops right up to the edge of the wheel tracks, while avoiding the tracks themselves.

Previously, part circle sprinklers usually came in the form of either fixed-spray or rotating stream devices – neither of which is geared towards maintaining a uniform application pattern. The Komet Precision Twister (KPT) PC-180 part circle sprinkler, on the other hand, is the first dry wheel track solution on the market to simultaneously provide an even distribution of optimally-sized droplets across the entire wetted area.